Product Overview

- Available in H13 (99.95% @ MPPS), and H14 (99.995% @ MPPS)

- Offers lowest possible pressure drop in terminal, panel HEPA filter

- Superior durability, hydrophobic nature, and chemically inert properties minimize risk

- Tolerant of high hydrocarbon exposure and high humidity

- Compatible with all validation test methods – photometer and discrete particle counter (DPC)

AAF International's eFRM Technology - Today's Alternative to Fragile Microglass HEPA Filters

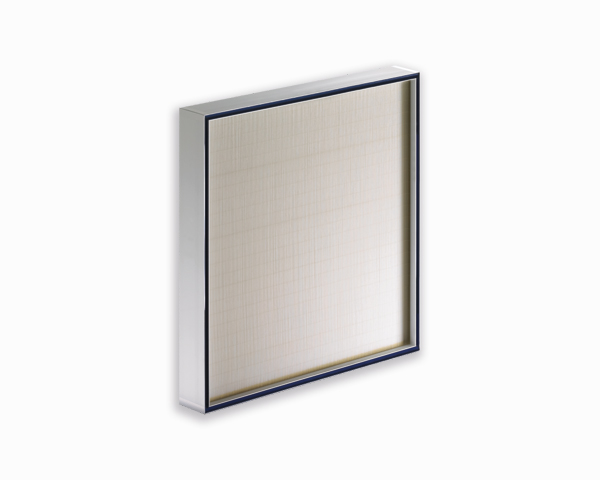

Designed specifically for the unique requirements and challenges of the pharmaceutical industry, the MEGAcel II mini-pleat HEPA filter has the proven durability, polyalphaolefin (PAO) compatibility, high particulate filtration efficiency, and the lowest pressure drop to meet the demands of pharmaceutical manufacturing. It is the best choice for the most demanding applications, saving both time and money while reducing contamination risk and invasive unscheduled downtime. With the lowest Total Cost of Ownership of all mini-pleat HEPA filters, the MEGAcel II will help protect your environment, reduce your business risk and optimise your clean air-related spending.

MEGAcel II is designed to increase cleanroom uptime and reduce the risks associated with pharmaceutical manufacturing Pharmaceutical-grade eFRM media is proven to be more durable than microglass, delivering superior performance Superior durability and tensile strength, 84 times the pleated strength of microglass Chemical-resistant capabilities reduce media degradation in highly corrosive environments Exceptional water resistance compared to ultrafine microglass

Extremely low off-gassing of chemical components, resulting in the highest quality clean air available

Lowest pressure drop mini-pleat HEPA filter available, reducing energy consumption for significant savings MEGAcel II and eFRM media are manufactured, tested and packaged in ISO 7 clean facilities to ensure the highest purity, quality, and consistency.

The pharmaceutical industry estimates that 77% of production downtime can be attributed to failures of equipment and environmental problems. This downtime can be caused by HEPA filters failing. Traditional HEPA filters typically fail due to some form of contact combined with the poor mechanical strength of the filter. The actions required when these failures occur include repairing/replacing the HEPA filter, certifying the repair or new installation, investigating a potentially contaminated product, and the generation of a risk assessment report. Effectively managing the risk and costs associated with successful operation requires utilising HEPA filters with dramatically higher tensile strength that are highly resistant to chemical degradation, thereby eliminating premature leaking and failure.

While FDA Testing Guidance requires critical room leak-testing certification twice a year, non-critical rooms require testing only once a year. With the extremely high tensile strength and durability of the eFRM pleated filter media, which is 84 times stronger than microglass, ISO 7 and 8 areas could be tested annually. Increasing time between certifications results in less PAO exposure to the gel seal (gel degradation), lower labour costs, and increased production time.

MEGAcel II -Testing with Discrete Particle Counter

With AAF’s new eFRM Media Technology, MEGAcel II filters can now be scan-tested with the industry standard photometer at the standard aerosol concentrations, as well as the low-aerosol concentration Discrete Particle Counter (DPC) method.

High Corrosion Resistance

eFRM Media Technology is proven to be resistant in highly corrosive environments, and will withstand attacks from common decontamination chemicals. Both components of the eFRM Media Technology, the membrane and non-woven layers, are stable against exposure at the prescribed time and concentration for the above disinfectant agents.

Superior Water Resistance

Based on AAF International's test lab results, eFRM Media Technology provides superior water resistance in comparison with ultrafine microglass, reducing damage risk.

Negligible Off-Gassing

eFRM Media Technology has extremely low off-gassing of chemical components, resulting in the highest quality clean air available.

- Healthcare

- Food & Beverage

- Pharmaceutical

- Biotechnology

- Animal Science

- Data Centers

FHK Polska

FHK Polska PureMedion Kft.

PureMedion Kft. Elfa spol. s r. o.

Elfa spol. s r. o. Ecotip d.o.o.

Ecotip d.o.o.