BioPharm company proves reliability of MEGAcel® II

- BioTechnique™ is a United States-based manufacturer of highly potent and cytotoxic sterile injectable biopharmaceuticals

- Located in Madison, Wisconsin

- BioTechnique manufactures:

- Liquid and lyophilised high value sterile injectable dosage forms for live attenuated viruses, antibody drug conjugates, nanoparticles and cytotoxics

- Products not amenable to terminal sterilisation that present specific environmental health and safety handling challenges to the manufacturing staff that handle them

Air handling represented a unique challenge to the BioTechnique facility, since all of the products that BioTechnique produces must be manufactured in an aseptic environment. If a HEPA filter was somehow compromised and did not provide at least a 99.97% reduction in non-viable particulates, it could cause potential microbial growth in a product required to be sterile. Risk assessment analysis showed a potentially critical impact to patients if non-sterile products were used, which was unacceptable.

A HEPA breach can be detected during the prescribed AQL sterility sampling of the product, during required environmental monitoring, or during the biannual HEPA certification process. However, a more substantial engineering solution was needed to ensure that the products manufactured by BioTechnique maintained the highest possible quality standards. After the product is formulated, filled, inspected, labelled, packaged, tested and released, there is no more opportunity to detect a quality issue. BioTechnique management therefore mandated, after assessing the potential impact to patient safety, that the Engineering Department seek a solution to improve the reliability of the manufacturing process and the quality of the product, while at the same time reducing the facility’s energy consumption.

In late 2014, the company embarked on a Lean Six Sigma project to improve the reliability of its manufacturing facility and reduce the energy costs of maintaining the Grade A (ISO 5), Grade B (ISO 6), Grade C (ISO 7) and Grade D (ISO 8) areas. National and local energy incentives, such as the State of California Title 24 programme, have encouraged many pharmaceutical firms like BioTechnique to initiate energy conservation projects.

BioTechnique undertook an engineering study to determine the return on investment by purchasing the new PAO compliant ePTFE filter media, compared to traditional glass media. The study was designed to determine the optimal filter pack depth of the ePTFE filter media to install, relative to the legacy microglass filter media.

To ensure no statistical bias, BioTechnique constructed a test rig that would allow testing in a controlled environment, ensuring that the testing methodology was statistically sound and reproducible, and would produce meaningful data to draw a defendable conclusion. The study was composed of tests that were conducted three times, each time using three filters of each type, including two traditional microglass HEPAs and the 50mm and 75mm ePTFE HEPA filters. This study therefore utilised 36 different tests, resulting in a statistically meaningful study.

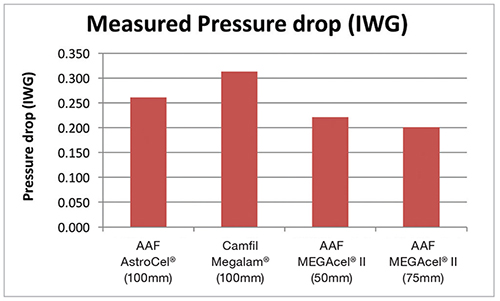

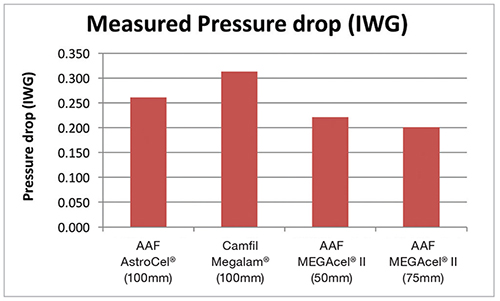

This graph represents the data collected in February 2015 for the four filter types. The ePTFE 50mm had approximately 30% less pressure drop than the 100mm microglass HEPA. The ePTFE 75mm had a 36% less pressure drop than the 100mm traditional microglass HEPA.

BioTechnique calculated the total projected annual energy savings due to the lower pressure drop ePTFE HEPA filters to be 9,350 kWh.

In October 2015, two competing sets of filters (AAF MEGAcel® II and Camfil Megalam®) were installed in two separate ISO 5 critical rooms and tested for FDA Certification multiple times.

Throughout the test run, MEGAcel II filters responded with a perfect 100% first pass success rate, while the Camfil filters recorded a disappointing 10.8% failure rate, requiring the filters to be replaced and retested.

The results confirmed that AAF's MEGAcel II Pharmaceutical Grade ePTFE Filtration Technology is not only completely PAO compatible, it also performs at the highest level in critical areas.

Because the MEGAcel II filters were significantly lighter, installation was accomplished with a single person, while the microglass HEPA filter install was a two-person job. This labour savings advantage was especially important when installing such a significant amount of filters. The filter could be held in one hand and a screwdriver in the other, allowing for a faster instalment. An additional advantage was the stress-free nature of the install—with the stronger and more robust filter, there was less worry about damage to the filter itself.

These tests demonstrated that HEPA filters constructed of ePTFE media are significantly stronger and more reliable than traditional microglass media.

- AAF’s MEGAcel II filters outperformed the competition with a 100% leak-free certification.

- ePTFE filters reduced filter failure and environmental monitoring excursions, resulting in lower production loss and labour costs.

- Utilising ePTFE filters increased BioTechnique’s time between recertifications, increasing cleanroom uptime.

- The lighter weight of the MEGAcel II filters allowed for a quicker installation—a labour savings advantage.

- ePTFE media has a dramatically lower pressure drop than traditional microglass media, resulting in significant energy savings for Grade A and Grade B cleanrooms.

- BioTechnique™ is a United States-based manufacturer of highly potent and cytotoxic sterile injectable biopharmaceuticals

- Located in Madison, Wisconsin

- BioTechnique manufactures:

- Liquid and lyophilised high value sterile injectable dosage forms for live attenuated viruses, antibody drug conjugates, nanoparticles and cytotoxics

- Products not amenable to terminal sterilisation that present specific environmental health and safety handling challenges to the manufacturing staff that handle them

Air handling represented a unique challenge to the BioTechnique facility, since all of the products that BioTechnique produces must be manufactured in an aseptic environment. If a HEPA filter was somehow compromised and did not provide at least a 99.97% reduction in non-viable particulates, it could cause potential microbial growth in a product required to be sterile. Risk assessment analysis showed a potentially critical impact to patients if non-sterile products were used, which was unacceptable.

A HEPA breach can be detected during the prescribed AQL sterility sampling of the product, during required environmental monitoring, or during the biannual HEPA certification process. However, a more substantial engineering solution was needed to ensure that the products manufactured by BioTechnique maintained the highest possible quality standards. After the product is formulated, filled, inspected, labelled, packaged, tested and released, there is no more opportunity to detect a quality issue. BioTechnique management therefore mandated, after assessing the potential impact to patient safety, that the Engineering Department seek a solution to improve the reliability of the manufacturing process and the quality of the product, while at the same time reducing the facility’s energy consumption.

In late 2014, the company embarked on a Lean Six Sigma project to improve the reliability of its manufacturing facility and reduce the energy costs of maintaining the Grade A (ISO 5), Grade B (ISO 6), Grade C (ISO 7) and Grade D (ISO 8) areas. National and local energy incentives, such as the State of California Title 24 programme, have encouraged many pharmaceutical firms like BioTechnique to initiate energy conservation projects.

BioTechnique undertook an engineering study to determine the return on investment by purchasing the new PAO compliant ePTFE filter media, compared to traditional glass media. The study was designed to determine the optimal filter pack depth of the ePTFE filter media to install, relative to the legacy microglass filter media.

To ensure no statistical bias, BioTechnique constructed a test rig that would allow testing in a controlled environment, ensuring that the testing methodology was statistically sound and reproducible, and would produce meaningful data to draw a defendable conclusion. The study was composed of tests that were conducted three times, each time using three filters of each type, including two traditional microglass HEPAs and the 50mm and 75mm ePTFE HEPA filters. This study therefore utilised 36 different tests, resulting in a statistically meaningful study.

This graph represents the data collected in February 2015 for the four filter types. The ePTFE 50mm had approximately 30% less pressure drop than the 100mm microglass HEPA. The ePTFE 75mm had a 36% less pressure drop than the 100mm traditional microglass HEPA.

BioTechnique calculated the total projected annual energy savings due to the lower pressure drop ePTFE HEPA filters to be 9,350 kWh.

In October 2015, two competing sets of filters (AAF MEGAcel® II and Camfil Megalam®) were installed in two separate ISO 5 critical rooms and tested for FDA Certification multiple times.

Throughout the test run, MEGAcel II filters responded with a perfect 100% first pass success rate, while the Camfil filters recorded a disappointing 10.8% failure rate, requiring the filters to be replaced and retested.

The results confirmed that AAF's MEGAcel II Pharmaceutical Grade ePTFE Filtration Technology is not only completely PAO compatible, it also performs at the highest level in critical areas.

Because the MEGAcel II filters were significantly lighter, installation was accomplished with a single person, while the microglass HEPA filter install was a two-person job. This labour savings advantage was especially important when installing such a significant amount of filters. The filter could be held in one hand and a screwdriver in the other, allowing for a faster instalment. An additional advantage was the stress-free nature of the install—with the stronger and more robust filter, there was less worry about damage to the filter itself.

These tests demonstrated that HEPA filters constructed of ePTFE media are significantly stronger and more reliable than traditional microglass media.

- AAF’s MEGAcel II filters outperformed the competition with a 100% leak-free certification.

- ePTFE filters reduced filter failure and environmental monitoring excursions, resulting in lower production loss and labour costs.

- Utilising ePTFE filters increased BioTechnique’s time between recertifications, increasing cleanroom uptime.

- The lighter weight of the MEGAcel II filters allowed for a quicker installation—a labour savings advantage.

- ePTFE media has a dramatically lower pressure drop than traditional microglass media, resulting in significant energy savings for Grade A and Grade B cleanrooms.

FHK Polska

FHK Polska PureMedion Kft.

PureMedion Kft. Elfa spol. s r. o.

Elfa spol. s r. o. Ecotip d.o.o.

Ecotip d.o.o.